Industrial Engine Non-Emergency Repair

For repairs that are not in response to a sudden breakdown or urgent issue, Colorado Standby takes proactive measures to address known problems, perform preventive maintenance, and ensure the long-term reliability and performance of your engine. Below are some common examples of non-emergency repairs for industrial diesel engines you may have.

Component Replacement

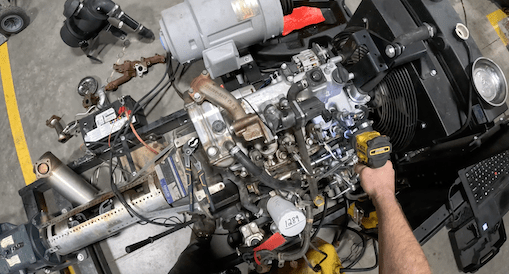

Replace worn-out or damaged components such as gaskets, seals, filters, belts, hoses, or bearings. This helps maintain optimal performance and prevent potential failures.Overhaul or Rebuilding

Conduct major repairs or engine overhauls, including cylinder head reconditioning, piston replacement, valve adjustments, or crankshaft repairs. Please see our overhaul and repower page for more information.

Fuel System Repair

Repair or replace fuel injectors, fuel pumps, fuel filters, and associated components to ensure proper fuel delivery and combustion efficiency. Fuel system repairs may also include adjustments to injection timing or calibration. All aspects of fuel delivery can be covered by our technicians.Cooling System Repairs

Repair of the cooling system, including coolant flush and refill, radiator repairs or replacement, replacement of hoses and clamps, and inspection or replacement water pumps. This helps prevent overheating and maintains optimal engine temperature.Electrical System Repairs

Diagnosis and repair of electrical system issues, including starter motors, alternators, batteries, wiring, and electrical connections. Our technicians can address electrical malfunctions, shorts, or failures to ensure reliable engine operation.Lubrication System Maintenance

Change engine oil and filters, inspect and clean oil coolers, and adjust or replace lubrication system components to ensure proper lubrication and minimize wear on engine parts.Exhaust System Repairs

Repair or replace exhaust components, DOC’s, SCR’s, sensors, pipes, or other emission related equipment. Our technicians look at leaks, corrosion, or damage to the exhaust system to maintain proper exhaust flow and emission control.Sealing and Gasket Replacement

Address leaks and replace worn-out gaskets, seals, or O-rings.General Cleaning and Inspection

Clean the engine and its components, remove carbon deposits, and conduct visual inspections to identify potential issues or areas of concern.

Contact Our Service Department

For more information, or if you are looking for a professional industrial diesel engine maintenance company that you can depend on, fill out our contact form or email us directly at [email protected] with any questions you may have.

If you prefer to speak to someone immediately, you can give us a call toll-free at 866-888-6111 option 3.